Igbe igbe Helical

Ihe eji ebu plastik Gearbox

Ngwongwo plastik extruder Gearbox, ndị na-emepụta igbe igbe extruder, igbe igbe maka ọrịre, igbe ndozi extruder gearbox, igbe ihe eji eme ihe, igbe ejima screw extruder gearbox

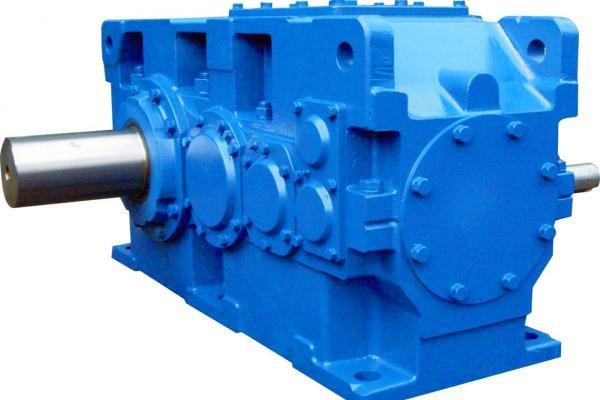

ZLYJ usoro siri ike n'elu gearbox bụ elu-nkenke nkenke ike-eze belt ntinye oche nnyefe akụrụngwa e mere maka plastic ịghasa extruder. Nhazi ngwaahịa na-anabata nkọwa teknụzụ akọwapụtara na JB/T8853-2001. Ọ na-egosipụta nchara alloy dị elu maka ngwa ngwa na akụkụ aro. A na-edozi ngwa ahụ site na carburizing, quenching na egweri. Gear ziri ezi bụ GB10095-88.6. Isi ike n'elu eze HRC54-62. A na-ahazi ihe nrịbama nke ukwuu na njedebe ihu nke ogwe mmepụta oghere iji guzogide ike axial na-arụ ọrụ nke ịghasa. A na-emepụta akụkụ ndị bụ isi ọkọlọtọ dị ka bearings na mmanụ mmanụ site na ngwaahịa dị elu nke ụlọ, a pụkwara ịkwado ya na ngwaahịa ndị a na-ebubata dị ka mkpa onye ọrụ si dị. Igwe ahụ dum nwere njirimara nke obere olu, ikike ibu dị elu, nnyefe kwụsiri ike, obere mkpọtụ na arụmọrụ dị elu. Nrụpụta ngwaahịa eruola ọkwa dị elu nke mba ụwa.

Atụmatụ ịrụ ọrụ:

Nchikota nke igbe na ntinye aka na-emegide ike axial, na a na-ahazi ihe na-emepụta ihe na ụlọ mmanụ nke gearbox iji meziwanye ntụkwasị obi arụ ọrụ.

Enwere ike iji obere mgbanwe dozie ebe etiti

Ike nnyefe dị elu, nwere ike iguzogide oke torque na ike axial

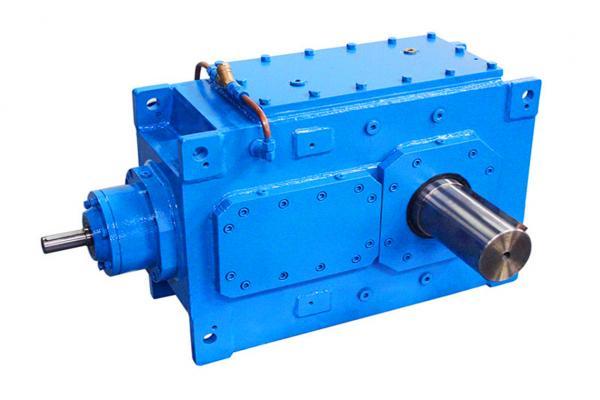

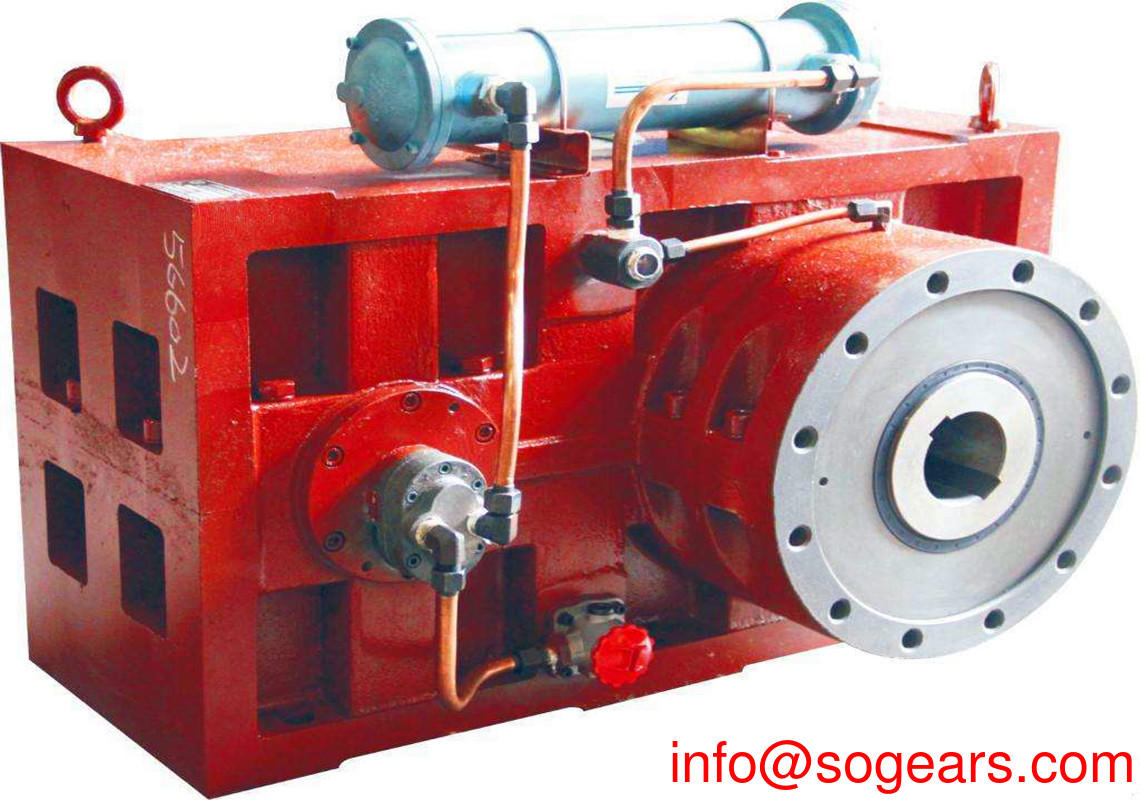

The pụrụ iche Gearbox maka extruder bụ a nnyefe akụrụngwa na elu ibu ikike siri ike eze elu na ntughari oche e mere na-ezo aka mba ọzọ yiri ngwaahịa maka plastic ịghasa extruder. Nhazi ngwaahịa ahụ nakweere nkọwa nka nka nke ZBJ19009-88 kwuru. Ihe e ji mara ya bụ na a na-eji ihe ndị na-emepụta ihe na ihe ndị na-emepụta ihe na-eme ka ọkpụkpụ na-arụ ọrụ dị elu, nke a na-edozi site na carburizing, quenching na egweri. Gear ziri ezi bụ GB10095-88, ọkwa 6. Isi ike nke eze HRC54 ~ 62. A na-ahazi ihe nrịbama nke buru ibu na njedebe n'ihu nke oghere ntinye oghere iji nagide mkpali axial nke kposara. Igwe ahụ dum nwere uru nke obere olu, ikike ibu dị elu, nnyefe kwụsiri ike, obere mkpọtụ na arụmọrụ dị elu.

Njirimara Gearbox pụrụ iche Extruder:

——Mkpụrụ modular, nnukwu nnyefe nso na mma na ezi uche nkesa;

— —Hadịdị ahụ dabara adaba maka nhazi ngwa nrụnye ụwa niile;

———Gia a na-eme ala site na igwe a na-agbanye igwe eji agbanye igwe eji eghe mmadu, na uda di ala na ezi oru 98% n'etiti usoro;

Igwe extrusion raara onwe ya nye Gearbox ọnọdụ ọdabara:

1. Ọsọ ọsọ ọsọ ọsọ ọsọ nke Gearbox abụghị ihe karịrị 1500r / min.

2, okpomọkụ gburugburu ebe ọrụ bụ 0-35C. Mgbe oke okpomọkụ karịrị ihe ndị a na-enye, enwere ike ịkwado ọkụ ma ọ bụ ngwaọrụ dị jụụ dịka onye ọrụ chọrọ.

- Okwu Mmalite

ZLYJ Plastic extruder Gearbox bụ ụdị mgbakọ gia siri ike dị elu nke emebere maka otu ihe nkedo rọba / rọba. Na-ewere JB/T 8853-2001 Cylindrical Plastic extruder Gearbox dị ka ntụaka maka imewe, ngwaahịa na-emetụta elu-ike ala-carbon alloy ígwè maka gia na gia aro, na eze flank carbureted, quenched na ala, izute gia nkenke na Level 6 (GB/T 10095) na ike nke nha nha nha HRC54 ~ 62. A na-etinye nnukwu ihe nrịbama n'ihu n'ihu ogwe mmepụta ka ọ na-ebuli ya site na ịghasa.

- Jiri Oke

- Ntugharị ntinye nke onye na-ebugharị ihe ga-abụ ≤ 1500 rpm.

- Ọsọ ọsọ nke gia ga-abụ ≤ 20m/s.

- Ọnọdụ okpomọkụ na-arụ ọrụ ga-adị n'ime -40 ℃ ~ 45 ℃. Kpoo mmanụ mmanụ ahụ n'elu 0 ℃ ma ọ bụ họrọ mmanụ na-ete mmanụ dị ala mgbe ọnọdụ okpomọkụ dị n'okpuru 0 ℃.

Cheta na:

- Ntughari dị ma ihu na azụ. Agbanyeghị, oghere dị elu nke ụfọdụ ụdị Plastic extruder Gearbox nwere mgbapụta mmanụ nwere otu ụzọ na-edobe ya na ogwe mmepụta nke na-atụgharị na elekere.

III. Plastic extruder Gearbox Ụdị

Mpempe aha ngwaahịa: Mgbe a na-ebuga ya, a na-ejikọta Gearbox Plastic extruder niile na mpempe aha iji kọwaa ụdị, ike, ụbọchị mmepụta, nọmba ụlọ ọrụ mbụ na atụmatụ ndị ọzọ maka nzube nke mmezi, nke a na-agaghị ewepụ na enweghị usoro.

- Nwụnye na njikọ nke Plastic extruder Gearbox

- Gbaa mbọ hụ na ntinye ntọala nke Plastic extruder Gearbox bụ larịị, echekwara ma kwụsie ike. Jiri nlezianya dobe nrụnye na ebe ọrụ pụrụ iche. Mgbe a na-ekechikwa ihe mgbochi arịlịka niile, hụ na ịtinye n'ime ogwe mmepụta na-atụgharị n'efu na mgbe niile.

- Njikọ nkwụ ụgwọ njehie ga-adị n'ihe gbasara njikọ nke Plastic extruder Gearbox na onye na-ebugharị. Gbaa mbọ hụ na ịdị n'otu akụkụ nke njikọ axial midline nke Plastic extruder nke ntinye ntinye Gearbox. Lelee ngbanwe nke axial na ntugharị angular, ntụgharị nke abụọ ga-adị n'ime uru a na-enye ohere nke njikọta etinyere.

- Lelee ogologo oge radial ọzọ nke oghere nke Plastic extruder Gearbox dị ka ihe nlele ngwaahịa si dị ma ọ bụrụ na ejiri wiil belt, gia na wheel yinye tinye ma wepụta ike ịkwọ ụgbọala nke Plastic extruder Gearbox. N'akụkụ etiti nke ntinye ntinye, ike radial ọzọ agaghị abụ karịa (N), nke ntinye oge nke Plastic extruder Gearbox (NM).

- Mgbe echichi gasịrị, jupụta na Plastic extruder Gearbox mmanụ na-ete mmanụ ruo mgbe ị ga-eru n'etiti ahịrị mmanụ mgbe ị na-ekesa nke ọma.

- Jikọọ na gbanye usoro mmiri jụrụ oyi ka ịlele ma nkwonkwo na-agba ọbara ma ọ bụ na-agbapụta.

- Gbanwuo ike ka ị na-agba ọsọ Plastic extruder Gearbox na-enweghị ibu. Lelee ma pipeline mmanụ ọ na-agbapụta ma ọ bụ na-agbapụta, akụkụ na akụkụ ndị ahụ na-atọpụ ma mkpọtụ ọ bụla na-eme. Enwere ike ịnyefe Gearbox Plastic extruder ma ọ bụrụ na ihe niile dị mma.

ige nti:

◇ Ebipụ ma gbochie (site na mkpado ịdọ aka ná ntị, wdg) njikọghachi nke ọkụ eletrik na moto tupu ịwụnye njikọ.

◇ A naghị anabata ịkụnye hama ma ọ bụ ngwaọrụ ndị ọzọ yiri ya mgbe ị na-agbanye njikọ na obere gia na njedebe ogwe.

◇ Gbaa mbọ hụ na mgbakasị ahụ ziri ezi nke eriri mgbe ị na-etinye wiil belt.

◇ Awụnyela ma ọ bụ wepụ ihe nkedo site na ike maka akụkụ mmepụta.

◇ A ga-enyerịrị mkpuchi mkpuchi n'akụkụ akụkụ na-atụgharị n'èzí nke Plastic extruder Gearbox (dị ka njikọ, eriri eriri, wdg).

◇ Wepu nke ọma mgbochi mgbochi, unyi ma ọ bụ ntụpọ ndị ọzọ na njedebe na flange elu nke ogwe njikọ. A na-anabata ihe mgbaze maka ihicha mana a ga-egbochi ya ịgbaba na akara egbugbere ọnụ nke ihe akara nke njedebe ogwe.

- Arụ ọrụ nke Plastic extruder Gearbox

Nlele tupu arụ ọrụ:

- Tupu ịrụ ọrụ, lelee ma Plastic extruder Gearbox nwere mmanụ na-ete mmanụ ruo ọkwa kwesịrị ekwesị n'ime ya. Tinye mmanụ ma ọ bụrụ na ụkọ.

- Akụkụ niile nke njikọ ga-abụ nke nchekwa. Ngwa nchekwa niile ga-ezu oke.

- Lelee ma gburugburu gburugburu ebe obibi dị n'okpuru 0 ℃, ọ bụrụ ee, kpoo mmanụ mmanụ ọkụ ka ọ dị elu 0 ℃.

Arụ ọrụ nke Plastic extruder Gearbox:

- Gbaa igbe mkpuchi plastik maka nkeji 5 ~ 10 na-enweghị ibu (ma ọ bụrụ na Plastic extruder Gearbox nwere igwe mgbapụta nke moto, malite mgbapụta mbụ) ka mma mmanu na bearings na gia. Ọ bụrụ na ejiri Gearbox Plastic extruder mee ihe maka oge mbụ, mgbe ọ na-agba ọsọ na-abaghị uru, gbakwunye ibu nzọụkwụ site na nzọụkwụ na 20% nke ibu e gosiri n'oge ọ bụla maka awa 1 ~ 2 ruo mgbe zuru oke. Tinye n'ọrụ ma ọ bụrụ na ihe niile dị mma.

- N'oge a na-arụ ọrụ, nyochaa na dee site n'oge ruo n'oge okpomọkụ ịrị elu nke Plastic extruder Gearbox. Ọ bụrụ na ịrị elu okpomọkụ nke Plastic extruder Gearbox karịrị 70 ℃ ma ọ bụ mmanụ ọkụ karịrị 100 ℃, kwụsị Plastic extruder Gearbox iji chọpụta na dozie nsogbu ahụ. Kpọtụrụ ngalaba ọrụ ịre ahịa ma ọ bụrụ na ọ dị mkpa. Dochie mmanụ na-ete mmanụ tupu ịmalite Plastic extruder Gearbox ọzọ.

- A ga-akwụsịkwa igbe Gear nke Plastic dị ka ndị a: Mechie hopper nri na, mgbe ebupuchara ihe niile dị na bọket ahụ, gbanyụọ ọkụ na-ebufe ihe na-ebufe plastik Gearbox (ọ bụrụ na ejiri ihe eji ebugharị plastik mee ihe. mgbapụta moto, mechie mgbapụta mbụ)

- Gbaa igbe Gearbox Extruder Plastic kwa izu 2 ruo 3 ma ọ bụrụ na ọ dị ogologo ndụ.

- Mee usoro mgbochi nchara n'ime na n'èzí nke Plastic extruder Gearbox ma ọ bụrụ na enweghị ọrụ karịrị ọnwa 6:

Jupụta mmanụ na-ete mmanụ ruo n'uju, yikwasị njedebe ogwe na elu na-enweghị ihe osise na ihe mgbochi nchara ma chebe ya na griiz griiz akara egbugbere ọnụ nke akara akụkụ nke axles megide ntinye nke mgbochi.

ige nti:

◇ N'oge mmalite nke ọrụ, mgbapụta mmanụ nwere ike ịkpata oké mkpọtụ sitere na viscosity dị elu nke mmanụ na-ete mmanụ na nnukwu nguzogide mmanụ ahụ megide mgbapụta mmanụ ahụ, nke ga-eji nwayọọ nwayọọ na-anwụ na okpomọkụ nke mmanụ mmanụ.

◇ Ọ bụrụ na mgbapụta mmanụ na-ebute oke mkpọtụ n'oge arụ ọrụ Plastic extruder Gearbox, hichaa ihe nzacha mmanụ ka o wee banye na pipeline mmanụ.

◇ Nyochaa site n'oge ruo n'oge mmanu mmanụ nke Plastic extruder Gearbox mgbe ọ na-arụ ọrụ, na, ọ bụrụ na ọ bụla, kwụsị Plastic extruder Gearbox iji dozie nsogbu ahụ.

- Mmezi na mmezi

- Ogologo oge nke nrụzi na mmezi

|

Oge nkeji |

Mmezi na ndozi |

|

Operationrụ ọrụ nkịtị |

Lelee okpomọkụ nke Plastics onye na –eme nti gearbox: ọ dịghị ihe karịrị 90 ℃ mgbe ị na-eji ịnweta mmanụ lubricating mmanụ ọ dịghị ihe karịrị 100 ℃ mgbe ị na-eji sịntetik lubricating mmanụ Lelee ma enwere mkpọtụ nke Plastic extruder Gearbox Lelee ma enwere mpụta nke Plastic extruder Gearbox |

|

Mgbe 500 ~ 800 awa ọrụ |

Mgbanwe mmanụ mmanụ mbụ mgbe arụchara ọrụ mbụ Lelee ọkwa mmanụ iji chọpụta njupụta mmanụ |

|

Kwa awa 3000 na-arụ ọrụ, ọ dịkarịa ala otu ugboro n'afọ |

Lelee mmanụ a na-ete mmanụ, na, ọ bụrụ na ọ dị n'èzí ma ọ bụ ebe dị mmiri mmiri, hụ na mmiri dị n'ime mmanụ mmanụ agaghị abụ ihe karịrị 500ppm. Dochie mmanụ lubricating ịnweta (awa ọrụ na-erughị 8h kwa ụbọchị) Hichaa plọg ikuku |

|

Dị ka ọ na-arụ ọrụ ọnọdụ, ọ dịkarịa ala otu ugboro 3 ọnwa |

Dochie mmanụ lubricating ịnweta (ọrụ ogologo oge na-aga n'ihu) Lelee ma ọ nwere ihe mgbochi nkwonkwo ọ bụla na-atọpụ Lelee ọnọdụ nke mmetọ na mmanụ mmanu na ngwaọrụ jụrụ oyi Hichaa nzacha mmanụ mmanu ma dochie isi nzacha ma ọ bụrụ na achọrọ ya |

|

Dị ka kwa ọnọdụ ọrụ, ọ dịkarịa ala otu ugboro n'afọ |

Dochie mmanụ na-ete mmanụ sịntetik |

|

Dị ka gburugburu na ọnọdụ ọrụ |

Meziwanye ma ọ bụ dochie ihe mkpuchi (rustproof) agba n'elu Hichaa elu mpụta na nke Plastic extruder Gearbox Lelee ngwaọrụ ngwa akwadoro |

- Ogologo oge nke nnọchi mmanụ mmanu mmanu

Dochie mmanụ mmanụ mgbe niile nke ụdị Plastic extruder Gearbox nke na-arụ ọrụ na gburugburu ebe siri ike. Ọnụ ọgụgụ dị n'okpuru ebe a na-egosi ogologo oge nke ndochi mmanụ mmanụ na gburugburu nkịtị. CLP HC na-ezo aka na mmanụ mmanụ sịntetik nke PAO.

(1) Oge ọrụ (2) okpomọkụ na-aga n'ihu na bat mmanụ (nkezi uru nke 70 ℃)

VII. Nyocha mmejọ na ngwọta

|

Mmejọ |

Eme |

Solutions |

|

Mmejọ |

Eme |

Solutions |

|

Mkpọtụ arụ ọrụ na-adịghị mma na mgbe niile |

A. Mkpọtu na-atụgharị/egwe ọka: ibu mebiri emebi B. Ụzụ ịkụ aka: ịgba ọsọ na-enweghị isi |

A. Lelee mmanu mmanu ma dochie ihe nkedo B. Kpọtụrụ Guomao |

Mwepu nke mmanụ mmanye: Nchikota elu nke Plastic extruder Gearbox Elu mkpuchi ngwụcha nke Plastic extruder Gearbox Mkpuchi oghere nke Plastic extruder Gearbox Ebe a na-emechi akwọ ụgbọala Nkwụnye mmanụ Ihe nkwụnye ikuku |

Ntọhapụ nke njikọ akụkụ nke Plastic extruder Gearbox Ntọhapụ nke njikọ njikọ Ntinye na-ezighi ezi nke akụkụ akara Mmebi / abrasion nke akụkụ akara Loose njikọ Oke mmanu mmanu mmanu mmanu Nwụnye ezighi ezi |

Lelee bolts njikọ wee mee ka ndị rụrụ arụ sie ike ma ọ bụrụ na achọrọ ya Lelee akụkụ akara ma dochie ya ma ọ bụrụ na achọrọ ya Lelee ọkwa mmanụ/ melite ike ọgwụgwụ Kpọtụrụ Guoma |

|

|

Mkpọtụ arụ ọrụ na-adịghị mma na nke na-adịghị adị |

Adịghị ọcha nke mmanu mmanu |

Lelee mmanụ mmanụ, kwụsị ọrụ wee kpọtụrụ Guomao |

||||

|

Mkpọtụ na-adịghị mma n'akụkụ ụfọdụ nke Plastic extruder Gearbox |

Ihe mgbochi nke Plastic extruder Gearbox na-atọpụ |

Lelee ihe nkedo ma jiri ndị ahụ akọwapụtara |

||||

|

Oke oke okpomọkụ nke ọrụ |

A. Ọtụtụ mmanụ na-ete mmanụ B. Ịka nká na mmebi mmanụ mmanụ C. Nnukwu adịghị ọcha na mmanụ mmanụ D. Mmebi nke mgbapụta mmanụ E. Mmejọ nke usoro jụrụ oyi |

A. Lelee ọkwa mmanụ ma mee mgbanwe ma ọ bụrụ na achọrọ ya B. Lelee oge nnọchi nke mmanụ mmanụ C. Lelee mmanụ mmanụ D. Lelee mgbapụta mmanụ ma dochie ya E. Lelee usoro jụrụ oyi |

Okpomọkụ dị oke elu na ibu |

A. Ezughi oke mmanu mmanu B. Ịka nká na mmebi mmanụ mmanụ C. Mmebi nke mgbapụta mmanụ D. Mmebi nke ibu |

A. Lelee ọkwa mmanụ ma mee mgbanwe ma ọ bụrụ na achọrọ ya B. Lelee oge nnọchi nke mmanụ mmanụ C. Lelee mgbapụta mmanụ ma dochie ya D Lelee ihe eji eme ya ma dochie ya |

|

|

Okpomọkụ karịrị oke na ebe akara akara nke ogwe njedebe na oge ịgba ọsọ |

Enweghị ihicha nke njikọ nke njedebe ogwe n'oge echichi Na-agba ọsọ nke akụkụ akara na njedebe ogwe |

Hichaa njedebe ogwe Were ya dị ka ihe nkịtị Kpọtụrụ Guoma |

Mgbe ị na-akpọtụrụ Guomao, biko nye ozi ndị a:

|

Mezue data n'ụdị aha |

- |

Ụdị na obosara nke mmejọ |

- |

Oge na phenomenae nke mmejọ mere |

- |

Eme |

VIII. Nhọrọ nke mmanu mmanu

A ga-ekpebi viscosity nke mmanụ mmanye n'otu n'otu n'akụkụ ọsọ V, gburugburu ebe ọrụ ma ọ bụ usoro mmanu mmanu nke ngwa ngwa ngwa ngwa:

Mgbe V≤2.5m / s ma ọ bụ ambient okpomọkụ dị n'ime 35 ℃ ~ 50 ℃, họrọ CKC320 ọkara-ibu ulo oru mechiri emechi gia mmanụ ma ọ bụ CKD320 arọ-ibu ulo oru mechiri emechi gia mmanụ;

Mgbe V-2.5m / s ma ọ bụ mmanye ekesa mmanye etinyere, họrọ CKC220 ọkara-ibu ulo oru mechiri emechi gia mmanụ ma ọ bụ CKD220 arọ-ibu ulo oru mechiri emechi gia mmanụ.

Obu mmanu

A naghị atụ aro mmanu mmanu maka igbe plastik extruder Gearbox. Kpọtụrụ anyị ma ọ bụrụ na achọrọ.

Lee Mgbakwunye-Tebụlụ ntụnyere mmanụ mmanu mmanu maka ngwaahịa mmanu mmanu mmanu nke ime obodo na nke mba ozo

- Yiri akụkụ

Ndepụta nke akụkụ eyi nke igbe ọkpọ extruder plastik

Ndepụta nkwakọ ngwaahịa nke igbe ọkpọ extruder plastik

Mgbakwunye - Tebụlụ ntụnyere mmanu mmanu (mmanụ mmanye nke ịnweta):

|

Category |

ISO VG |

AGMA |

Supplier |

Ụdị mmanu mmanu mmanu |

Viscosity / 40 ℃ |

Ebe na-ekpo ọkụ ℃ |

|

Category |

ISO VG |

AGMA |

Supplier |

Ụdị mmanu mmanu mmanu |

Viscosity / 40 ℃ |

Ebe na-ekpo ọkụ ℃ |

|

220 |

220 |

5 EP |

December |

Degol BG220 |

220 |

-21 |

320 |

320 |

6 EP |

December |

Degol BG320 |

320 |

-18 |

|

|

BP |

Energol GR-XP220 |

210 |

-27 |

BP |

Energol GR-XP320 |

305 |

-24 |

|||||||

|

Castrol |

Alfa SP220 |

220 |

-21 |

Castrol |

Alfa SP320 |

320 |

-21 |

|||||||

|

Castrol |

Alfamax 220 |

220 |

-24 |

Castrol |

Alfamax 320 |

320 |

-18 |

|||||||

|

Chevron |

Ụlọ ọrụ mmanụ EP220 |

220 |

-12 |

Chevron |

Ụlọ ọrụ mmanụ EP320 |

320 |

-9 |

|||||||

|

chi nwaanyị |

Falcon CLP220 |

220 |

-18 |

chi nwaanyị |

Falcon CLP320 |

320 |

-18 |

|||||||

|

Esso |

Spartan EP220 |

226 |

-30 |

Esso |

Spartan EP320 |

332 |

-27 |

|||||||

|

Exxon |

Spartan EP220 |

226 |

-30 |

Exxon |

Spartan EP320 |

332 |

-27 |

|||||||

|

Fuchs |

Renolin CLP220 Plus |

223 |

-23 |

Fuchs |

Renolin CLP320 Plus |

323 |

-21 |

|||||||

|

Ọwara |

Gulf EP mmanu HD220 |

219 |

-19 |

Ọwara |

Gulf EP mmanu HD320 |

300 |

-12 |

|||||||

|

Klüber |

Klüberoil GEM 1-220 |

220 |

-15 |

Klüber |

Klüberoil GEM 1-320 |

320 |

-15 |

|||||||

|

Kuwait |

Q8 Goya 220 |

220 |

-21 |

Kuwait |

Q8 Goya 320 |

320 |

-18 |

|||||||

|

Mobil |

Mobilegear 630 |

207 |

-18 |

Mobil |

Mobilegear 632 |

304 |

-18 |

|||||||

|

Mobil |

Mobilgear XMP 220 |

220 |

-24 |

Mobil |

Mobilgear XMP 320 |

320 |

-18 |

|||||||

|

Molub-Alloy |

MA-90/220 |

220 |

-18 |

Molub-Alloy |

MA-90/320 |

320 |

-15 |

|||||||

|

Optimol |

Optigear BM220 |

233 |

-15 |

Optimol |

Optigear BM320 |

338 |

-15 |

|||||||

|

Petro Canada |

Ultima EP220 |

223 |

-30 |

Petro Canada |

Ultima EP320 |

320 |

-21 |

|||||||

|

Shell |

Mmanụ Omala F220 |

220 |

-21 |

Shell |

Mmanụ Omala F320 |

320 |

-18 |

|||||||

|

Texaco |

Meropa 220 |

209 |

-21 |

Texaco |

Meropa 320 |

304 |

-18 |

|||||||

|

Total |

Carter EP220 |

220 |

-12 |

Total |

Carter EP320 |

320 |

-12 |

|||||||

|

Tribol |

Tribol 1100/220 |

222 |

-25 |

Tribol |

Tribol 1100/320 |

317 |

-23 |

|||||||

|

GB5903-95 |

Ọ bụ |

CKC220 |

198 ~ 242 |

≤-8 |

GB5903-95 |

Ọ bụ |

CKC320 |

288 ~ 352 |

≤-8 |

|||||

|

GB5903-95 |

Ọ bụ |

NKD220 |

198 ~ 242 |

≤-8 |

GB5903-95 |

Ọ bụ |

NKD320 |

288 ~ 352 |

≤-8 |

|||||

Mgbakwunye - Tebụl ntụnyere mmanụ na-ete mmanụ (mmanụ mmanu mmanu sịntetik PAO):

|

Category |

ISO VG |

AGMA |

Supplier |

Ụdị mmanu mmanu mmanu |

Viscosity cSt |

Ebe na-ekpo ọkụ ℃ |

|

Category |

ISO VG |

AGMA |

Supplier |

Ụdị mmanu mmanu mmanu |

Viscosity cSt |

Ebe na-ekpo ọkụ ℃ |

||

|

40 ℃ |

100 ℃ |

40 ℃ |

100 ℃ |

|||||||||||||

|

220 |

220 |

5 EP |

chi nwaanyị |

Ntinye HCLP220 |

220 |

25.1 |

-36 |

320 |

320 |

6 EP |

chi nwaanyị |

Ntinye HCLP320 |

320 |

33.9 |

-33 |

|

|

Esso |

Spartan sịntetik EP220 |

232 |

26.5 |

-39 |

Esso |

Spartan sịntetik EP320 |

328 |

34.3 |

-36 |

|||||||

|

Exxon |

Spartan sịntetik EP220 |

232 |

26.5 |

-39 |

Exxon |

Spartan sịntetik EP320 |

328 |

34.3 |

-36 |

|||||||

|

Fuchs |

Renolin Unisyn CLP220 |

221 |

25.8 |

-42 |

Fuchs |

Renolin Unisyn CLP320 |

315 |

33.3 |

-39 |

|||||||

|

Klüber |

Klübesynth EG 4-220 |

220 |

26 |

-40 |

Klüber |

Klübesynth EG 4-320 |

320 |

38 |

-40 |

|||||||

|

Mobil |

Mobilgear SHC XMP 220 |

220 |

28.3 |

-45 |

Mobil |

Mobilgear SHC XMP 320 |

320 |

37.4 |

-39 |

|||||||

|

Mobil |

Mobilgear SHC 220 |

213 |

26 |

-51 |

Mobil |

Mobilgear SHC 320 |

295 |

34 |

-48 |

|||||||

|

Optimol |

Optigear Synthic A220 |

210 |

23.5 |

-36 |

Optimol |

Optigear Synthic A320 |

290 |

30 |

-36 |

|||||||

|

Shell |

Mmanụ omala HD220 |

220 |

25.5 |

-48 |

Shell |

Mmanụ omala HD320 |

320 |

33.1 |

-42 |

|||||||

|

Texaco |

Ọnụ ego EP220 |

220 |

25.8 |

-48 |

Texaco |

Ọnụ ego EP320 |

320 |

35.2 |

-39 |

|||||||

|

Total |

Carter EP/HT220 |

220 |

25 |

-39 |

Total |

Carter EP/HT320 |

320 |

33 |

-36 |

|||||||

|

Tribol |

Tribol 1510/220 |

220 |

24.6 |

-42 |

Tribol |

Tribol 1510/320 |

330 |

33.2 |

-39 |

|||||||

|

Tribol |

Tribol 1710/220 |

220 |

- |

-33 |

Tribol |

Tribol 1710/320 |

320 |

- |

-30 |

|||||||

|

Ọ bụ |

Nnukwu Mgbidi |

4405/220 |

221.3 |

- |

-42 |

|

|

|

|

|

|

|||||

|

Ọ bụ |

Nnukwu Mgbidi |

4406/220 |

225.3 |

- |

-42 |

Ọ bụ |

Nnukwu Mgbidi |

4406/320 |

330.5 |

- |

-40 |

|||||

Otu ịghasa extruder ụkpụrụ

A na-ekewakarị otu ịghasa n'ime akụkụ atọ n'ogologo dị irè. A na-ekpebi ogologo oge dị irè nke akụkụ atọ dị ka dayameta nke ịghasa na pitch nke ịghasa. N'ozuzu, a na-ekewa ya na otu ụzọ n'ụzọ atọ.

A na-akpọ eriri ikpeazụ nke ọdụ ụgbọ mmiri ahụ ngalaba nnyefe: a chọrọ ka ọ bụrụ plastik ebe a, mana ọ ga-eburịrịrịrị ya ma kpoo ya. N'oge gara aga, ozizi extrusion ochie kwenyere na ihe dị n'ebe a bụ nke rụrụ arụ, ma mesịa gosi na ihe dị ebe a bụ n'ezie Plọg siri ike, ya bụ, ihe dị ebe a bụ ihe siri ike dị ka nkwụnye mgbe emechara ya, ya mere, ọ bụ ya. ọrụ ya ma ọ bụrụhaala na a rụchara ọrụ mbufe.

A na-akpọ akụkụ nke abụọ ngalaba mkpakọ. N'oge a, a na-eji nwayọọ nwayọọ belata olu nke oghere ahụ site na nnukwu na nnukwu, na okpomọkụ ga-eru ogo nke plasticization nke ihe. N'ebe a, a na-emepụta mkpakọ ahụ site na ngalaba nnyefe nke atọ, bụ ebe a na-ejikọta ya na otu, nke a na-akpọ mkpakọ mkpakọ nke ịghasa - 3: 1, ụfọdụ ígwè ọrụ agbanwewokwa, na ihe a rụchara nke plastik na-abanye na ọkwa nke atọ.

Akụkụ nke atọ bụ akụkụ nke mita, ebe ihe ahụ na-ejigide okpomọkụ plasticizing, dị nnọọ ka n'ụzọ ziri ezi na quantitatively na-ebufe ihe gbazere dị ka mgbapụta mita iji nye isi, n'oge ahụ okpomọkụ enweghị ike ịdị ala karịa okpomọkụ plasticizing, n'ozuzu ntakịrị elu. .

Onye nchịkọta akụkọ nchekwa ike Extruder

Enwere ike kewaa nchekwa ike nke extruder n'ime akụkụ abụọ: otu bụ akụkụ ike na nke ọzọ bụ akụkụ ọkụ.

Nchekwa ike: A na-eji ọtụtụ n'ime ihe ntụgharị. Ụzọ nchekwa ike bụ ịchekwa ike fọdụrụnụ nke moto. Dịka ọmụmaatụ, ezigbo ike nke moto bụ 50Hz, ma ị chọrọ naanị 30Hz na mmepụta iji mepụta nke ọma. Ngafe ike oriri bụ ihe efu. Efufuo, onye inverter bụ ịgbanwe ike mmepụta nke moto iji nweta ike ịzọpụta.

Ichekwa ike na akụkụ kpo oku: Ọtụtụ n'ime nchekwa ike na kpo oku bụ ịzọpụta ike site na ọkụ ọkụ eletrik, yana ọnụego nchekwa ike bụ ihe dịka 30% ~ 70% nke mgbanaka resistor ochie.

usoro ọrụ

Ihe plastik na-abanye na extruder site na hopper, a na-ebuga ya n'ihu site na ntụgharị nke ịghasa. N'oge mmegharị ahụ na-aga n'ihu, ihe ahụ na-ekpo ọkụ site na gbọmgbọm ahụ, na-akpụ ya site na ịghasa na abịakọrọ iji gbazee ihe. Ya mere, a na-enweta mgbanwe n'etiti steeti atọ nke iko iko, ọnọdụ dị elu na-agbanwe agbanwe, na ọnọdụ viscous na-asọpụta.

N'ihe banyere pressurization, ihe na a viscous eruba ala na-agafere site a anwụ na-enwe a ụfọdụ udi, na mgbe ahụ na-aghọ a continuum na-enwe a cross-ngalaba na a ọnụ-dị ka anya dị ka ndị nwụrụ anwụ. Mgbe ahụ, a na-eme ka ọ dị jụụ ma mee ka ọ bụrụ ọnọdụ enyo, si otú ahụ nweta akụkụ a ga-edozi.

Onye ndezi ihe mejupụtara

Na extruder, n'ozuzu, ihe kachasị mkpa na nke kachasị dị iche iche bụ otu ihe nkedo. Ọ gụnyere: akụkụ isii: nnyefe, ngwaọrụ nri, gbọmgbọm, ịghasa, isi igwe na anwụ.

Ngalaba nnyefe

Akụkụ nnyefe na-ejikarị moto eletrik, igbe mbelata na bearings. N'oge usoro extrusion, ịghasa ọsọ ga-eguzosi ike na-enweghị ike ịgbanwe na mgbanwe nke ịghasa ibu ibu, ka ịnọgide na-enwe otu àgwà àgwà nke nwetara. Otú ọ dị, n'oge dị iche iche, a pụrụ ịchọ ka skru ahụ gbanwee iji nweta ihe a chọrọ na otu ngwaọrụ nwere ike ịpụpụ plastik dị iche iche ma ọ bụ ngwaahịa dị iche iche. Ya mere, akụkụ a n'ozuzu na-eji AC commutator moto, DC moto na ngwaọrụ ndị ọzọ iji nweta stepless ọsọ mgbanwe, izugbe ịghasa ọsọ bụ 10 ~ 100 rev / min.

Ọrụ nke usoro nnyefe bụ ịkwọ ụgbọ mmiri ahụ, nke na-enye ike na ọsọ ọsọ nke screw chọrọ n'oge usoro extrusion, na-enwekarị moto, Gearbox na bearing. N'okpuru echiche na ihe owuwu ahụ bụ otu ihe ahụ, ọnụ ahịa nrụpụta nke Gearbox dabara na akụkụ mpụga ya na ịdị arọ ya. N'ihi na ọdịdị na ịdị arọ nke Gearbox buru ibu, ọ pụtara na e nwere ọtụtụ ihe ndị a na-eri n'oge a na-emepụta ihe, na bearings na-ejikwa dị oke ibu, nke na-abawanye ọnụ ahịa mmepụta ihe.

Ngwa nri

Ọtụtụ n'ime nri nri bụ pelletized, ma ibe ma ọ bụ ntụ ntụ nwekwara ike iji. Ngwa nchaji na-ejikarị conical hopper nwere olu chọrọ ma ọ dịkarịa ala otu awa. A na-enye ngwaọrụ a na-emechi emechi na ala nke hopper iji dozie ma belata mmiri ahụ, na-etinyekwa oghere anya na ngwaọrụ mita n'akụkụ akụkụ nke hopper. Ụfọdụ hoppers nwekwara ike ịnwe ngwaọrụ enyemaka nrụgide ma ọ bụ ngwaọrụ kpo oku nke na-egbochi nri nri ka ọ ghara ịmịkọrọ mmiri site na ikuku, ma ọ bụ ụfọdụ n'ime cartridges nwekwara ike ịnwe mkpali nke ha maka inye nri ma ọ bụ inye nri.

Onye nlekọta

A na-emekarị hopper n'ụdị symmetrical. A na-emeghe windo n'akụkụ nke hopper iji hụ ọkwa ihe na ọnọdụ nri. Ala nke hopper nwere oghere oghere na mmechi iji kwụsị ma mezie ọnụọgụ nri. Na-ekpuchi elu nke hopper iji gbochie uzuzu, mmiri na adịghị ọcha ịdaba na ya. Mgbe ị na-ahọrọ ihe nke hopper, ọ kacha mma iji ihe dị arọ, nke na-eguzogide corrosion na dị mfe na igwe, na-ejikarị aluminum na igwe anaghị agba nchara. Olu nke hopper na-adabere na nha nke extruder na usoro ntinye. N'ozuzu, ọnụ ọgụgụ extrusion nke extruder bụ site na 1 ruo 1.5 awa.

Enwere ụdị ụzọ nri abụọ: inye aka na nri akpaaka. Nri na-akpaghị aka gụnyere nri mmiri, nri mgbawa, nri agụụ, ibufe eriri na ihe ndị yiri ya. N'ozuzu, a na-eji aka na-ebugharị obere extruders na nnukwu extruders na-akpaghị aka.

Nhazi nke ụzọ nri

1 Nri ike ndọda:

Ụkpụrụ - Ihe na-abanye n'ime gbọmgbọm site n'ịdị arọ nke ya, gụnyere nri akwụkwọ nri, nri mmiri, na ịgbawa.

Atụmatụ - usoro dị mfe na ọnụ ala dị ala. Otú ọ dị, ọ dị mfe ime ka nri na-enweghị isi, nke na-emetụta àgwà nke akụkụ ahụ. Ọ bụ naanị adabara obere size extruders.

2 nri mmanye:

Ụkpụrụ - Wụnye ngwaọrụ na hopper nke na-etinye nrụgide mpụga na ihe ahụ, na-amanye ihe ahụ n'ime gbọmgbọm nke extruder.

Atụmatụ - nwere ike imeri ihe omume "akwa" ahụ, nke mere na nri ahụ bụ ọbụna. The ndepụta ịghasa na-chụpụrụ site extruder ịghasa site mbanye yinye ka mezie ya ọsọ na ịghasa ọsọ. Enwere ike ịgbanye ngwaọrụ nchebe oke ibu mgbe egbochiri ọdụ ụgbọ mmiri, si otú a na-ezere mmebi nke ngwaọrụ nri.

katrij

N'ozuzu, ọ bụ gbọmgbọm ihe igwe nke ejiri ígwè alloy ma ọ bụ ọkpọkọ nchara jikọtara ya na ígwè alloy. Njiri mara ya bụ oke okpomọkụ na nguzogide nrụgide, ike eyi na nguzogide corrosion. N'ozuzu, ogologo gbọmgbọm ahụ bụ 15 ruo 30 ugboro dayameta ya, na ogologo ya bụ nke na ihe ahụ na-ekpo ọkụ nke ọma na plasticized n'otu n'otu. gbọmgbọm ahụ kwesịrị inwe oke na isi ike. Ime ime kwesịrị ịdị nro, mana ụfọdụ n'ime gbọmgbọm ka a na-eji oghere dị iche iche kanye esemokwu na plastik. A na-enye ndị na-ekpo ọkụ ọkụ eletrik, ngwaọrụ nchịkwa okpomọkụ na usoro jụrụ oyi n'èzí nke gbọmgbọm na resistors, inductor na ụzọ ndị ọzọ nke kpo oku.

Enwere ụdị ihe atọ dị na gbọmgbọm ahụ:

(1) integral gbọmgbọm

Usoro nhazi - edozi ya na ihe niile.

Uru - dị mfe iji hụ na nrụpụta dị elu na nhazi nhazi, nwere ike ime ka ọrụ mgbakọ dị mfe, cylinder na-ekpo ọkụ nke ọma, na ngwa ndị ọzọ.

Ihe ọghọm - N'ihi nnukwu ogologo gbọmgbọm na ihe nhazi dị elu, ihe ndị a chọrọ maka akụrụngwa nhazi dịkwa oke siri ike. Ihe dị n'ime ime gbọmgbọm ahụ siri ike ịrụzi mgbe eyichara.

(2) Ngwakọta ihe

Usoro nhazi - a na-edozi gbọmgbọm ahụ n'ọtụtụ ọkwa, mgbe ahụ, a na-ejikọta akụkụ ndị ahụ site na flanges ma ọ bụ ụdị ndị ọzọ.

Uru - nhazi dị mfe, dị mfe ịgbanwe akụkụ akụkụ, nke a na-ejikarị eme ihe iji gbanwee akụkụ nke ịghasa.

Mwepu - elu nhazi nkenke chọrọ, n'ihi na ọtụtụ akụkụ, ọ na-esiri ike hụ na coaxiality nke ọ bụla nkebi, na flange njikọ agbaji uniformity nke gbọmgbọm kpo oku, na-abawanye okpomọkụ ọnwụ, kpo oku na jụrụ usoro ntọala na mmezi siri ike karị.

(3) gbọmgbọm bimetallic

Usoro nhazi - Kponye ma ọ bụ tụba akwa akwa nchara n'ime ala nke ígwè carbon nkịtị ma ọ bụ nkedo ígwè. Ọ bụghị naanị na ọ na-ezute ihe ndị a chọrọ nke gbọmgbọm ahụ, kamakwa ọ na-echekwa ihe metal dị oké ọnụ ahịa.

1 Bushing cartridge: A na-etinye katrij ahụ na nchara nchara na-agbanwe agbanwe. Ịchekwa ọla ndị dị oké ọnụ ahịa, enwere ike dochie bushes ahụ, na ndụ nke gbọmgbọm na-abawanye. Ma imewe ya, nrụpụta na mgbakọ dị mgbagwoju anya karị.

2 Nkedo gbọmgbọm: A na-atụba oyi akwa nke ihe dị ka mm abụọ n'obosara alloy na centrifugally na mgbidi dị n'ime gbọmgbọm ahụ, wee nweta dayameta dị n'ime nke gbọmgbọm ahụ site n'igweri. A na-ejikọta oyi akwa alloy nke ọma na isi nke gbọmgbọm ahụ, na njikọ n'akụkụ ogologo axial nke gbọmgbọm ahụ bụ otu, enweghị ọchịchọ ịpụpụ, ọ dịghị agbawa, nwere arụmọrụ dị mma na-amị amị, ma nwee nnukwu mgbochi na-eyi. ogologo ndu.

1) A na-emeghe oghere ogologo ogologo nke mgbidi dị n'ime nke ngalaba nri gbọmgbọm

Iji mee ka ọnụ ọgụgụ njem njem siri ike dị elu, otu ụzọ bụ ịbawanye ọnụọgụ nke esemokwu nke elu nke cylinder site na echiche njem siri ike. Ụzọ ọzọ bụ ịbawanye ebe ihe dị na ọdụ ụgbọ mmiri site na akụkụ obe perpendicular na axis skru. Nhazi nke uzo ogologo n'ime mgbidi dị n'ime nke ngalaba nri gbọmgbọm na taper nke mgbidi dị n'ime akụkụ nke akụkụ nri dị nso n'ọdụ ụgbọ mmiri bụ kpọmkwem ụzọ abụọ ahụ.

2) Amanye jụrụ oyi ngalaba ngalaba gbọmgbọm

E nwekwara usoro iji mee ka ọnụ ọgụgụ siri ike na-ebufe. Ọ bụ iji mee ka gbọmgbọm ngalaba nri dị jụụ, ebumnuche bụ idobe okpomọkụ nke ihe a ga-ebuga n'okpuru ebe dị nro ma ọ bụ ihe na-agbaze, iji zere ọdịdị nke ihe nkiri gbazere iji nọgide na-enwe ihe mgbagha siri ike nke ihe ahụ.

Site na usoro a dị n'elu, a na-abawanye arụmọrụ nnyefe site na 0.3 ruo 0.6, na ọnụ ọgụgụ nke extrusion na-enwechaghị mmetụta maka mgbanwe na nrụgide isi.

Ihe nkedo bụ obi nke extruder na bụ isi ihe dị na extruder. Arụmọrụ nke ịghasa na-ekpebi arụpụtaghị ihe, plasticizing àgwà, mgbasa nke ndochi, gbazee okpomọkụ, ike oriri, wdg nke extruder. . Ọ bụ akụkụ kachasị mkpa nke extruder, nke nwere ike imetụta ngwa ngwa ngwa na mmepụta mmepụta nke extruder. Ntughari nke ịghasa na-eme ka nrụgide dị ukwuu na plastik. Plastic nwere ike ịkwaga, kpagide ma nweta ụfọdụ okpomọkụ site na esemokwu dị na cylinder. A na-agwakọta plastik na plasticized n'oge mmegharị nke cylinder ahụ, na ọnọdụ viscous na-agbaze A na-eme ka agbaze ahụ na-eme ka ọ bụrụ na a na-agbapụta ya ka ọ na-agafe na ọnwụ iji nweta ọdịdị a chọrọ. Dị ka gbọmgbọm ahụ, a na-emekwa ihe nkedo ahụ nke ike dị elu, okpomọkụ na corrosion eguzogide alloy.

N'ihi ụdị plastik dị iche iche, ihe onwunwe ha dịkwa iche. Ya mere, na arụ ọrụ n'ezie, iji mee ka ọ dị iche iche nhazi nhazi plastik dị iche iche, ụdị nke screws chọrọ dị iche iche, na ihe owuwu dị iche iche. Iji mee ka arụmọrụ nke plastik dịkwuo elu iji mee ka njem, extrusion, ịgwakọta na plasticization.

Foto a na-egosi ọtụtụ skru ndị ọzọ a na-ahụkarị. Ihe ndị bụ isi na-egosi njirimara nke ịghasa gụnyere ihe ndị a: dayameta, akụkụ akụkụ, oke mkpakọ, pitch, omimi omimi, akụkụ helix, screw na barrel, na ihe ndị yiri ya. Dayameta nke ịghasa D kachasị adịkarị bụ ihe dịka 45 ruo 150 mm. Ka screw dayameta na-abawanye, ikike nhazi nke extruder na-abawanye otú ahụ, na mmepụta nke extruder na-adabere na square nke ịghasa dayameta D. The ratio nke irè ogologo na dayameta nke na-arụ ọrụ akụkụ nke ịghasa (na-ezo aka). dị ka akụkụ akụkụ, nke egosipụtara dị ka L/D) na-abụkarị 18 ~ 25. Nnukwu L/D nwere ike imeziwanye nkesa okpomọkụ ihe onwunwe, mee ka ngwakọta na plasticization nke plastik dị mfe, ma belata ntapu na nlọghachi azụ.

Meziwanye ikike mmepụta nke extruder, L / D nnukwu ịghasa nwere ike ime mgbanwe ma nwee ike iji ya mee ihe maka extrusion nke plastik dị iche iche; Otú ọ dị, mgbe L / D buru ibu, a ga-emebi plastik site na oge kpo oku na ịghasa Mgbe ịdị arọ nke onwe ya na-abawanye, njedebe n'efu na-atụgharị na sag, nke na-eme ka ihe dị mfe kpụchaa n'etiti ịghasa na ịghasa, ma mee ka usoro mmepụta ihe sie ike; ike oriri nke extruder na-abawanye. Ihe mkpirisi nke dị mkpụmkpụ nwere ike ime ka plasticization na-adịghị mma nke igwakorita.

A na-akpọ ọkara nke ọdịiche dị n'etiti oghere dị n'ime nke gbọmgbọm na dayameta nke ịghasa ahụ oghere δ, nke nwere ike imetụta mmepụta nke extruder. Ka δ na-abawanye, nrụpụta na-ebelata. Ọtụtụ mgbe, njikwa δ dị mma maka 0.1 ruo 0.6 mm. δ dị obere, a na-edobe ihe ahụ na-enwe mmetụta dị ukwuu nke ịkpụcha ihe, nke bara uru na plasticization, ma δ dị oke ntakịrị, ihe siri ike na-eme ka ọ dị mfe na-eme ka ọkụ ọkụ na-emebi ihe, ma n'otu oge ahụ, a na-ekowe ihe nkedo ahụ ngwa ngwa ma ọ bụ. rubbed megide mgbidi nke cylinder ahụ, na Mgbe δ dị ntakịrị, ọ fọrọ nke nta ka ọ bụrụ nkwụsịtụ ma ọ bụ azụghachi nke ihe ahụ, nke na-emetụta ngwakọta nke gbazee ruo n'ókè ụfọdụ.

Oghere helix Φ bụ akụkụ dị n'etiti eri na akụkụ obe nke ịghasa. Ka Φ na-abawanye, mmepụta nke extruder na-abawanye, ma mmetụta nke ịkpụ na ike ịpị na plastik na-ebelata. Ọtụtụ mgbe, akụkụ helix dị n'etiti 10 ° na 30 degrees. N'etiti Celsius, tinyere ntụziaka nke mgbanwe nke ogologo nke ịghasa, mgbe mgbe na-eji ihe equidistant ịghasa, na-ewere pitch hà dayameta, uru nke Φ bụ banyere 17 ° 41 '

Ka oke mkpakọ dị, ka oke mkpakọ nke plastik na-enweta. Mgbe oghere ahụ na-emighị emi, ọ nwere ike ịmepụta ọnụ ọgụgụ dị elu maka plastik, nke bara uru na nnyefe ọkụ n'etiti mgbidi nke gbọmgbọm na ihe. Ihe dị elu nke ngwakọta ihe na ịrụ ọrụ plasticizing, na-ebelata mmepụta ihe; n'ụzọ megidere nke ahụ, oghere dị omimi. Ọnọdụ dị nnọọ iche. Ya mere, a ga-eji ihe ndị na-ekpo ọkụ na-ekpo ọkụ (dị ka polyvinyl chloride) mee ihe na nkedo miri emi; maka plastik nwere viscosity dị ala na nkwụsi ike dị elu (dị ka polyamide), ekwesịrị iji skru na-emighị emi mee ihe.

1. Nkebi nke ịghasa

Mgbe ihe na-aga n'ihu na nkedo ahụ, ọ na-enwe mgbanwe na okpomọkụ, nrụgide, viscosity, wdg. Mgbanwe a dị iche n'ime ogologo ogologo nke ịghasa. Dị ka àgwà na-agbanwe agbanwe nke ihe ahụ, enwere ike kewaa ihe nkedo ahụ n'ime akụkụ ihe onwunwe na-agbakwụnye (eziga) na mkpakọ. Nkeji na homogenization ngalaba.

1. Steeti atọ nke rọba na rọba

Plastics nwere ụdị thermosetting abụọ na thermoplastic. Mgbe emechara plastik na-ekpo ọkụ na-ekpo ọkụ ma gwọọ ya, enweghị ike ikpo ọkụ na gbazee ha. Enwere ike ịmegharị ihe a na-emepụta thermoplastic ma gbazee n'ime isiokwu ndị ọzọ.

Ka okpomọkụ na-agbanwe, thermoplastic na-emepụta mgbanwe nke steeti atọ nke iko, ọnọdụ dị elu na ọnọdụ viscous. Mgbanwe ugboro ugboro na okpomọkụ, steeti atọ na-emepụta mgbanwe ugboro ugboro.

a. Njirimara dị iche iche nke polymer gbazere na steeti atọ:

Ọnọdụ iko - plastik na-egosi dị ka ihe siri ike siri ike; Thermal ngagharị ike dị obere, intermolecular ike dị ukwuu, deformation bụ tumadi so site deformation nke njikọ n'akuku; mgbe e wepụrụ ike mpụga, a na-eweghachi nrụrụ ahụ ozugbo, bụ nke nrụrụ izugbe.

Ọnọdụ na-agbanwe nke ukwuu - plastik bụ ihe dị ka roba; nrụrụ na-enye aka site na nhazi nke mgbatị macromolecular kpatara site na nhazi nke akụkụ ahụ, uru nrụrụ dị ukwuu; mgbe e wepụsịrị ike dị n'èzí, enwere ike weghachite nrụrụ ahụ ma dabere na oge, nke bụ nnukwu nrụrụ dị elu.

Viscous eruba steeti-plastic na-apụta dị ka nnukwu viscous agbaze; The thermal energy na-eme ka mmegharị ahụ nke yinye ụmụ irighiri ihe dị n'ime ya sie ike; nrụrụ bụ ihe a na-apụghị ịgbagha agbagha ma bụrụ nke nrụrụ plastik

b. Nhazi plastik na steeti tri-state:

Enwere ike ime ya na iko plastik. Nhazi ịgbatị na steeti na-agbanwe dị elu, dị ka ịse waya, extrusion ọkpọkọ, ịkpụzi ihe na temometa. N'ime ọnọdụ viscous na-asọpụta, enwere ike kpuchie ya, rotomolded na ịkpụzi injections.

Mgbe okpomọkụ dị elu karịa ọnọdụ viscous eruba, rọba ahụ ga-ere ọkụ na-ekpo ọkụ, na mgbe okpomọkụ dị ala karịa ọkwa iko, plastik ga-agbaji. Mgbe okpomọkụ plastik dị elu karịa ọkwa viscous ma ọ bụ dị ala karịa ọkwa iko, thermoplastic na-eme ka ọ bụrụ nke ọma na-emebi ma bibie ya, ya mere a ga-ezere mpaghara okpomọkụ abụọ ahụ mgbe ị na-edozi ma ọ bụ na-eji ngwaahịa plastik.

Ọnụ ụzọ na windo profaịlụ bụ nke PVC ntụ ntụ. Plastic extruder Gearbox na-eji ọtụtụ ebe dị ka windo na ọnụ ụzọ profaịlụ, yana ihe ịchọ mma. Site na nkà na ụzụ ọgbara ọhụrụ na nhazi kachasị mma, ọ nwere ihe onwunwe nke ikike mmepụta dị elu, ogologo ndụ na plastik mee ihe.

Plastic extruder Gearbox bụ ụdị mmepụta akara e mere maka extrusion nke PVC plastic doos na windo profaịlụ na cross-ngalaba nkwurịta okwu cable ọkpọkọ, Aluminom-plastic mejupụtara profaịlụ, wdg O nwere ike plastification, elu mmepụta, ala sheering ike, ogologo ndụ ọrụ. na uru ndị ọzọ. Enwere ike iji profaịlụ PVC mee ihe na ụlọ ọrụ ụlọ na ụlọ ma ọ bụ ụlọ ọrụ.

Lubrication na jụrụ oyi, kpo oku

A na-eji ọdọ mmiri mmanụ na splashes na-ete mmanụ gia na bearings. Na mgbakwunye na mmanu mmanu, Usoro ZLYJ siri ike elu gearbox na n'elu bearings ka agbakwunyere na mmanụ mgbapụta mmanu usoro maka mmanye mmanye mmanye.

Ogo mmanụ na-ete mmanụ bụ mmanụ mgbali elu nke ọkara N220 ma ọ bụ mmanụ skating ọzọ dị elu nwere viscosity yiri ya.

Mgbe ọnọdụ okpomọkụ dị n'okpuru 0 Celsius, a na-agbakwunye ọkpọkọ ọkụ eletrik na ọdọ mmiri mmanụ iji kpoo mmanụ mmanụ ọkụ.

Mgbe ọnọdụ okpomọkụ dị elu karịa 35 Celsius C, ụlọ ọrụ anyị na-arụ ọrụ nguzozi okpomọkụ dịka ọnụ ahịa okpomọkụ nke onye ọrụ nyere iji chọpụta ma ọ ga-abawanye ngwaọrụ jụrụ oyi.

ZLYJ usoro cylindrical bevel gearbox Ụdị igbe gia siri ike:

Nkọwapụta bụ: ZLYJ112, 133, 146, 173, 200, 225, 250, 280, 315, 330, 375, 420, 450; SJY224, 250, 280, 315; ZSYJ315, 375, 395, 420, 450, 560; 6E , 7E, 8E, 9E, 10E, 12E, 15E, JHM na ndị ọzọ rọba na roba ụlọ ọrụ-kpọmkwem gearbox (nwere ike ahaziri maka dị iche iche na-abụghị ọkọlọtọ nnukwu gearboxs).

Single ịghasa extruder Single ịghasa plastic extruder maka plastic extruder igwe

Ezi ekele kachasị,

Cherry Zhang (Ngalaba Ahịa; Miss.)

NER GROUP CO., AHIM

Yantai Bonway Manufacturer Co., Ltd.

Tel: + 86-535-6330966

Ekwentị: + 86-18865558975

www.planetary-gearbox.com

https://twitter.com/gearboxmotor

https://www.facebook.com/sogears1993

Viber / Line / Whatsapp / WeChat: 008618865558975

E-mail:

Tinye: No.5 Wanshoushan Road Yantai obodo Shandong Province, China

Ọrụ kachasị mma site na ọkachamara nnyefe ọkachamara na igbe mbata gị ozugbo.

anyị Service

Bịanụ na Touch

Yantai Bonway Manufacturer Co.ltd

Ano.160 Changjiang Road, Yantai, Shandong, China(264006)

T + 86 535 6330966

W + 86 185 63806647